Low Volume: 10-1000 pieces

High Precision Tolerance: ±0.003 mm

Tricky Metallic Materials: Stainless Steel, Titanium Alloy

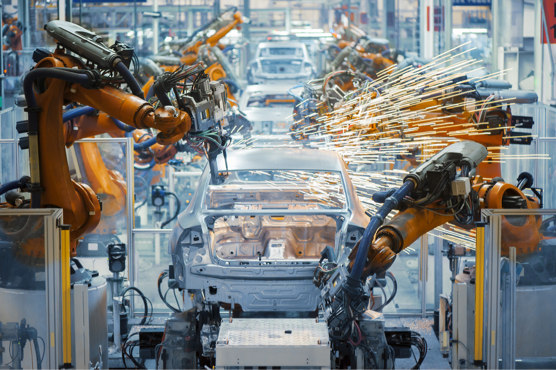

Industry: Military, Aerospace, Petroleum Exploration, Automovite

Our ISO 9001 certified factory is equipped with a wide range of CNC machines such as 5 axis CNC machines, turning, milling, and drilling machines for precision CNC machining. Constructing complex prototypes,workpieces and products with superior precision of 0.003mm is feasible through our CNC milling and turning. We strictly comply with DIN 2768 standards to manufacture, ensuring your CNC machining custom is constructed right the first time. Master of tricky and rigid metallic materials has helped us earn great reputation from various industries such as automotive, aerospace and more.

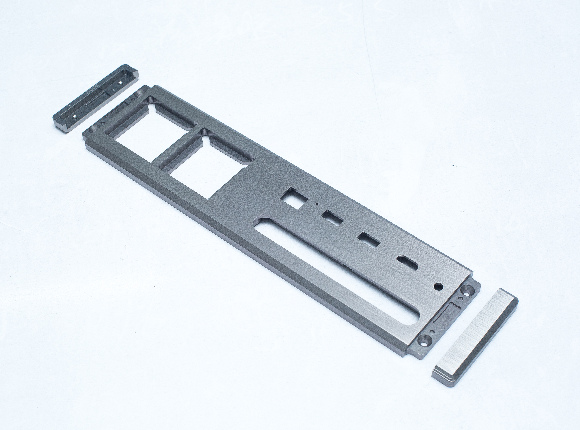

As a subtractive manufacturing process, our CNC milling involves 3-axis milling and 5-axis indexed milling processed to cut solid metal blocks into workpieces for finalized products.

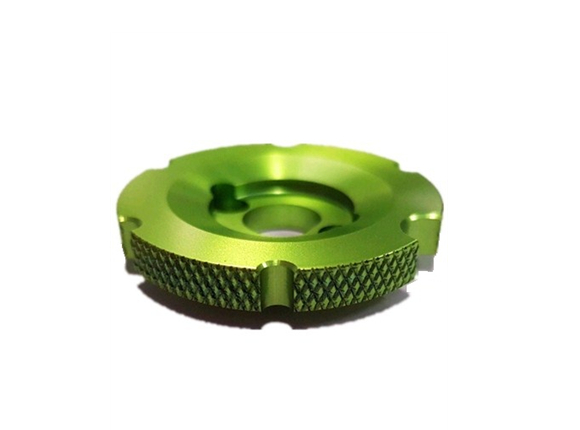

To create round or tubular-shaped workpieces from rigid metallic materials, our CNC turning utilizes advanced CNC processing machines and cutting-edge software to realize high precision.

Achieving custom plastic injection molding is possible through our advanced machinery and expert design processes that meet your requirements.

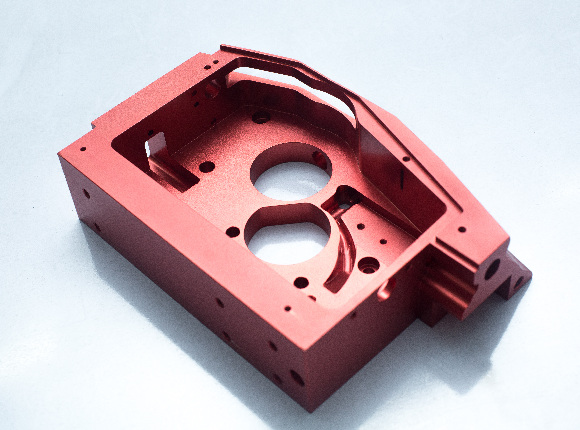

Long-term partnerships with the military field has given us deep understanding towards the specific needs of the sector. We’ve supplied the market with highly-optimized products that exhibit better resistances to corrosion and temperature changes, as well as increased durability.

The aerospace market requires products and parts that have great resistances to fatigue and heat, along with high-precision matching connectivity. Working with high-precision 5-axis machining and fixtures, we deliver exceptional parts and 7A04 materials that the market deeply appreciates.

As the products are exposed to harsh weather conditions and extreme elements, the industry requires products made from hard materials like titanium alloy with minimal tolerances. TH Molding manufactures precision parts with deep hole drilling equipment with a concentricity of 3000mm+/-0.3mm.

DFM analysis is conducted before manufacturing to review for any potential challenges with the build, validate material requirements, and manage the tolerance within +/-0.01mm. Quality control is observed throughout the production process, with dimensional inspection reports available upon request.

TH Molding has taken several companies to the next level through our unmatched CNC machining benefits.

TH Molding engineers excel at metal CNC machining where the minimum tolerance is 0.003mm, ensuring accurate production and prototyping.

Professional 3-axis, 4-axis, and 5-axis machining equipment are operated within our workshop as well as a deep hole drilling machine that can achieve 3 +/-0.3 meters.

The engineering team consists of 5 CNC programming masters and CNC lathe professionals with more than 10 years of working in the CNC machining industry.

By having a mature supply chain and in-house production, TH Molding ensures a competitive price and low CNC machining cost.

The skills of our engineer enable us to process hard and difficult metallic materials such as stainless steel, titanium alloy, and more.

To ensure the quality of all workpieces, we are familiar with various manufacturing standards of DME, PCS, HASCO, and more.

As the data shown below, TH Molding offers better CNC machining solutions in terms of production capabilities and available materials.

| Name | Information | Description |

| MOQ: | 1 | Whether you want to fulfill rapid prototyping or low volume production, we always get you covered. |

| Minimum Tolerance: | ± 0.003mm | We utilize advanced machines such as Charmilles EDM machines, FANUC CNC machines, and more. |

| Average Tolerance: | 0.02mm | We excel at designing and manufacturing high precision metal prototypes and workpieces. |

| Advanced Machine: | 150 | We have more than 150 CNC machines ranging from Mikron CNC machine, Makino EDM machine, LAGUN milling machine and more. |

| Fast Lead Time: | 3 Days | Fast CNC Machining can be as fast as 3 days. |

| Achievable Materials: | Metal: aluminum alloy, stainless steel, steel, copper, iron, titanium alloy -4 718, K500, 7A04, and more. | We can support various kinds of CNC machining ranging from rigid metallic materials. View more materials. |

Take inspiration from the products that TH Molding has assisted with over the years.

Quality and speed are maintained throughout the inclusive capabilities thanks to our fully integrated in-house workshops and latest production equipment.

Our experts are available 24/7 and ready to address any concern regarding technical support or after sales.

Have some questions regarding our prototyping and low-volume manufacturing service? Visit our FAQ page for the information you need.

Check out how our strong rapid prototyping services addressed the needs of our clients worldwide.

Talk to our experts today and let TH Molding help you bring your concepts to life and start elevating your brand!

Since 2000, we have engaged in prototyping and low-volume production. We are committed to offering the most cost-efficient and rapid prototyping and manufacturing solutions.

Supported File: STP, STEP, IGS, X_T, PRT, DXF, DWG