TH Molding as a professional rapid prototyping company excels at designing and producing high-quality, low-volume prototypes, making us the perfect one-stop shop for all your rapid prototyping needs. We utilize mature rapid prototyping technology with unmatched service, with capabilities to produce functional plastic, metal, and sheet metal prototypes in as fast as three days.

With rapid prototyping, you can properly understand how your product presents and easily make adjustments before committing to full-swing production.

See how your design looks firsthand, making it more efficient than conducting a trial-and-error process with multiple molds.

Compared to design drawings or visual concepts, physical models empower designers to share concepts with colleagues with tangible examples.

Rapid prototyping allows for proper evaluation of the final product and performs necessary adjustments, especially on limited product cycles.

Access to a prototype helps eliminate costly design flaws that might have been missed during preliminary assessments.

Since setup and additional tooling won’t be required in rapid prototyping, time and resources are saved and allocated on where it is needed.

TH Molding dedicates extra time, energy, and resources to guarantee that your prototypes are made exactly to your specifications and make changes based on your feedback.

We promote flexibility for our rapid prototyping process, not limiting ourselves to an order quantity to give the service you need.

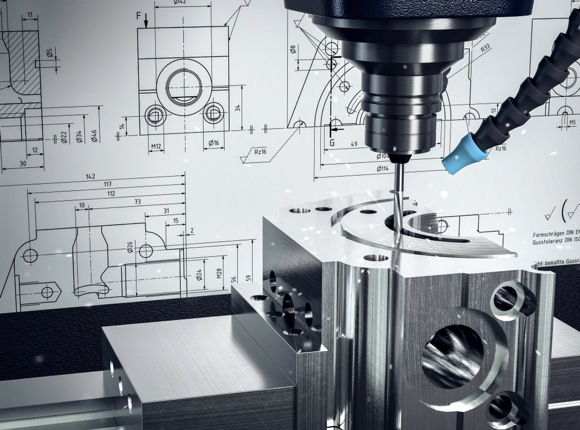

To improve quality of production, we utilize advanced rapid prototyping technologies and equipment, such as CNC turning, milling, and drilling machines.

Rely on our engineers to deliver unmatched service. They are skilled with design software and are experts in reverse engineering and product optimization.

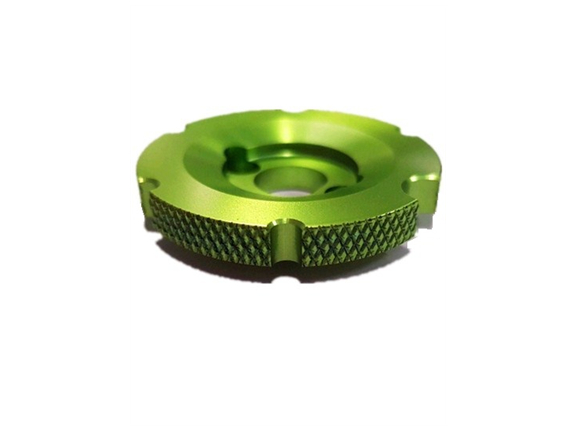

Included in our rapid prototyping service is our full-scale surface treatment that is based on your project needs.

With the combination of our experience handling rapid prototyping materials and a wide supply network, we can work with any material your project demands.

Our strong production capability and seasoned engineers guarantee rapid prototyping projects are completed as early as three days from the request.

To complete your prototypes, we offer a complete range of secondary processing components that makes the process more inclusive and hassle-free. From surface treatment to in-house assembly, we take care of everything else you need under one roof.

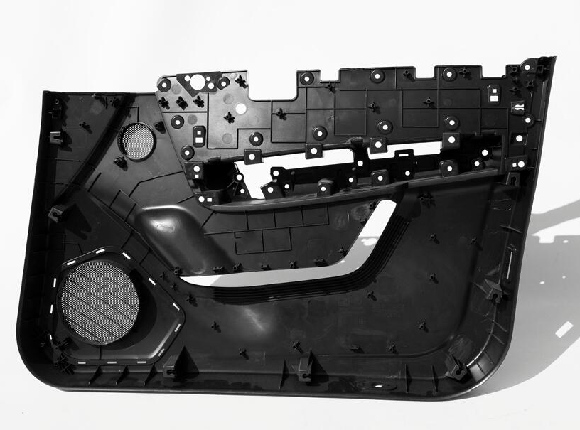

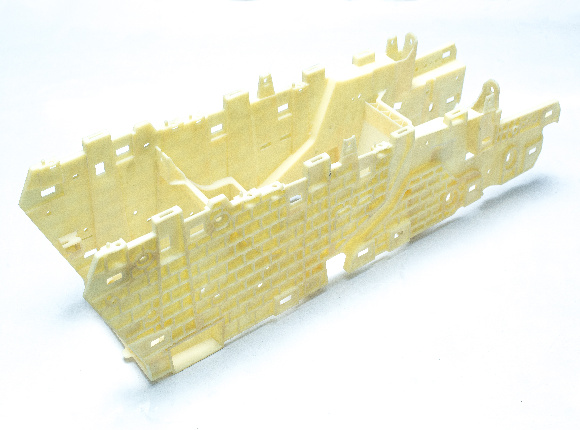

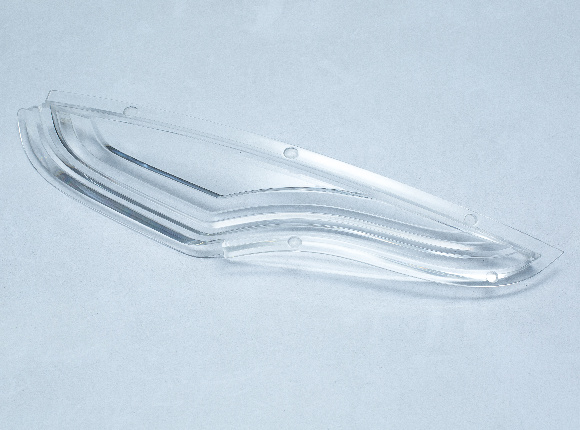

Take inspiration from the products that TH Molding has assisted with over the years.

Quality and speed are maintained throughout the inclusive capabilities thanks to our fully integrated in-house workshops and latest production equipment.

Our experts are available 24/7 and ready to address any concern regarding technical support or after sales.

Have some questions regarding our prototyping and low-volume manufacturing service? Visit our FAQ page for the information you need.

Check out how our strong rapid prototyping services addressed the needs of our clients worldwide.

Talk to our experts today and let TH Molding help you bring your concepts to life and start elevating your brand!

Since 2000, we have engaged in prototyping and low-volume production. We are committed to offering the most cost-efficient and rapid prototyping and manufacturing solutions.

Supported File: STP, STEP, IGS, X_T, PRT, DXF, DWG